The Caprolactam Market Outlook provides a comprehensive look into the supply and demand dynamics of a key chemical used primarily in the production of nylon 6, a high-performance polymer. Caprolactam is an essential intermediate compound in the manufacture of synthetic fibers, engineering plastics, and resins, which find extensive applications across industries such as textiles, automotive, electronics, and consumer goods. As of 2024, the global caprolactam market stood at a volume of around 7,000 Kilo Tons, with projections indicating a steady growth rate of 3.00% CAGR from 2025 to 2034, ultimately reaching a market volume of 7,440.72 Kilo Tons by 2034.

This article delves into the various factors that influence the caprolactam market, including raw material supply, technological advancements, regulatory changes, and evolving market trends. We will examine key demand drivers, regional dynamics, and the future outlook for caprolactam, providing insights for both industry professionals and non-technical readers interested in understanding the market's trajectory.

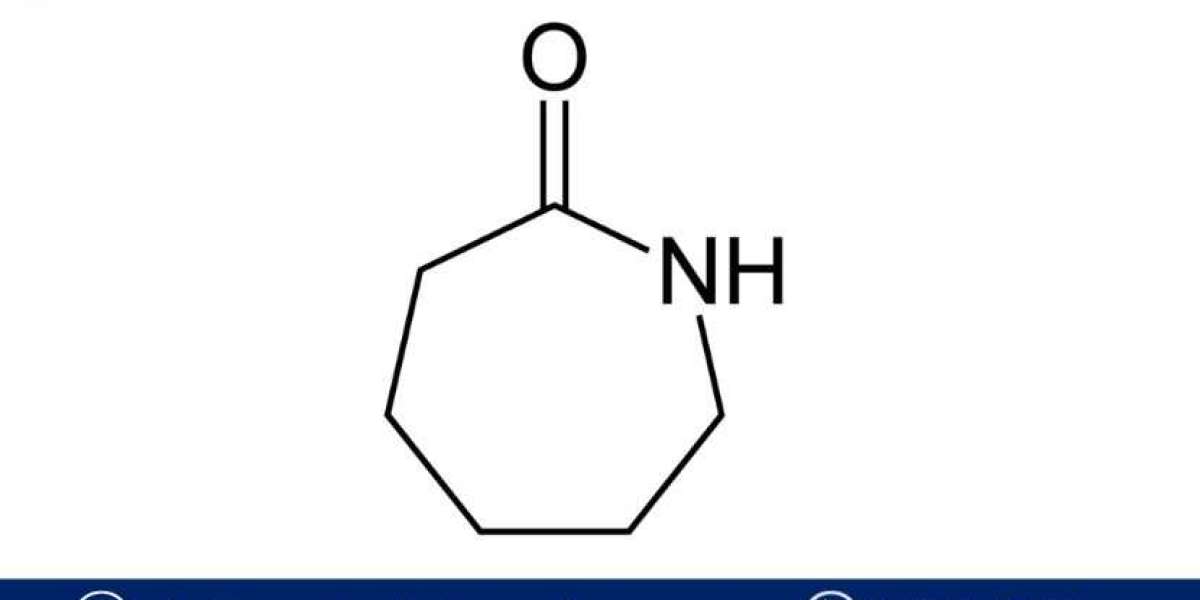

Understanding Caprolactam and Its Importance

Caprolactam is a cyclic amide that is primarily used as a monomer in the production of nylon 6, one of the most widely used synthetic fibers and plastics. Nylon 6 is a versatile material with exceptional strength, resilience, and heat resistance, making it ideal for use in automotive parts, textiles, consumer goods, industrial applications, and electrical and electronic components.

Caprolactam is synthesized via the polymerization of its monomer, and its demand is closely linked to the consumption of nylon 6. The growth of industries that rely on these high-performance materials significantly drives the caprolactam market. As the world moves towards more sustainable and energy-efficient solutions, the importance of caprolactam as a raw material for nylon 6 and other polymer products continues to rise.

Get a Free Sample Report with Table of Contents@

https://www.expertmarketresearch.com/industry-statistics/caprolactam-market/requestsample

Current State of the Caprolactam Market

As of 2024, the global caprolactam market volume stands at approximately 7,000 Kilo Tons. The market is projected to grow at a compound annual growth rate (CAGR) of 3.00% between 2025 and 2034, reaching around 7,440.72 Kilo Tons by 2034. This steady growth is attributed to several key drivers, which we will explore in the following sections.

Demand Drivers for Caprolactam

Textile and Apparel Industry: One of the primary drivers of caprolactam demand is the textile and apparel industry. Nylon 6 is a core material in the production of fabrics, carpets, and other textile products, owing to its durability, flexibility, and resistance to wear and tear. The increasing demand for high-quality and long-lasting textile products, coupled with the rise in global consumer spending on apparel, contributes to the growing consumption of caprolactam.

Automotive Industry: The automotive industry is another significant consumer of caprolactam, as nylon 6 is used in the manufacturing of various automotive components, including under-the-hood parts, fuel lines, and bumpers. With growing demand for lightweight and durable materials in automotive manufacturing, caprolactam’s role in producing high-strength materials for these applications is expected to increase.

Consumer Goods and Electronics: Caprolactam is also widely used in the production of consumer goods such as electrical components, sports equipment, and household items. The rising demand for durable, high-performance materials in these industries, driven by technological advancements and shifting consumer preferences, supports caprolactam market growth.

Packaging Industry: Nylon 6, derived from caprolactam, is increasingly being used in packaging applications, especially for food packaging, due to its excellent barrier properties, which help in preserving the freshness and shelf life of products. The growing demand for packaged goods in emerging economies is thus driving caprolactam consumption.

Sustainability and Eco-friendly Trends: Caprolactam’s use in the production of sustainable materials is an important trend, particularly in the automotive and textiles sectors, which are working towards reducing environmental footprints. Advances in recycling technologies for nylon 6 and the development of bio-based caprolactam are contributing to the market’s future growth potential.

Supply-side Challenges

On the supply side, caprolactam production is dependent on a few key raw materials, including cyclohexane, ammonia, and other petrochemical derivatives. The production process is energy-intensive and requires access to stable, cost-effective feedstocks. The availability and price volatility of raw materials, particularly petrochemical-based inputs, can impact the supply of caprolactam and, in turn, its pricing dynamics.

Moreover, the global caprolactam market is concentrated in a few key manufacturing regions, particularly in Asia Pacific, North America, and Europe. Asia Pacific holds a significant share of the global production, with countries like China, India, and South Korea being major producers. The region is experiencing high demand across multiple industries, leading to increased production capacity and investments in new technologies to improve manufacturing processes and reduce costs.

However, disruptions in the supply chain, such as those caused by geopolitical factors, environmental regulations, or natural disasters, can affect the global supply of caprolactam and create price fluctuations.

Regional Insights and Trends

Asia Pacific: The Leading Market

Asia Pacific continues to be the largest and fastest-growing market for caprolactam, with China being the dominant player in the region. China’s rapid industrialization and growing consumer market have contributed to an increasing demand for nylon 6, particularly in the textile, automotive, and packaging sectors. The country’s capacity to produce caprolactam at competitive prices, coupled with large-scale domestic demand, has positioned Asia Pacific as the center of global production and consumption.

India and Southeast Asia are also experiencing growth in caprolactam consumption, driven by expanding textile manufacturing, rising consumer demand for durable products, and infrastructure development. As these economies continue to develop and industrialize, their demand for caprolactam will continue to rise.

North America and Europe: Steady Growth

In North America and Europe, the caprolactam market remains stable, with moderate growth projections. Both regions are focused on sustainability and innovation, driving the adoption of eco-friendly production methods and the development of bio-based caprolactam. As consumer preferences shift towards sustainable products, industries in these regions are turning to caprolactam as a key component in creating high-performance, eco-friendly materials.

The United States and Western European countries have seen growth in automotive and packaging sectors, where the use of caprolactam-derived nylon 6 is increasing due to its durability and environmental benefits. These markets are also keen on investing in recycling technologies and bio-based alternatives, which will continue to influence the demand for caprolactam in the years to come.

Technological Advancements and Future Trends

The caprolactam market is seeing several technological advancements that are enhancing production efficiency and environmental sustainability. Some of these innovations include:

- Bio-based Caprolactam: With increasing emphasis on sustainability, there has been growing research into bio-based caprolactam derived from renewable sources such as biomass. This shift toward bio-based alternatives is driven by the need to reduce carbon emissions and dependence on petrochemical feedstocks. Companies like DSM and other key players in the market are investing in these technologies to meet the rising demand for sustainable solutions.

- Improved Manufacturing Processes: Innovations in caprolactam production technologies are focusing on reducing energy consumption and improving yield. New catalytic processes and optimized distillation techniques are being explored to enhance the efficiency of caprolactam manufacturing while minimizing waste and operational costs.

- Recycling of Nylon 6: The increasing emphasis on recycling and reusing materials is another critical trend in the caprolactam market. Nylon 6, derived from caprolactam, can be recycled and reused in various applications, contributing to the circular economy and reducing the need for new caprolactam production. Advancements in nylon 6 recycling technologies will help further support the sustainable growth of the caprolactam market.

Sustainability Considerations

Sustainability remains a central theme in the caprolactam market, driven by both regulatory requirements and consumer demand for greener alternatives. The production of caprolactam and the use of nylon 6 in products are energy-intensive, which makes reducing the carbon footprint a priority for the industry.

In response, companies are focusing on improving the energy efficiency of caprolactam manufacturing and exploring renewable feedstocks. Additionally, the development of more efficient recycling methods for nylon 6 is expected to play a crucial role in mitigating the environmental impact of caprolactam production.

Related Reports

https://www.expertmarketresearch.com/articles/top-sportswear-companies

Media Contact

Company Name: Claight Corporation

Contact Person: Peter Fernandas, Corporate Sales Specialist — U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au